Datacer 4

Here is our final Datacer post, our next update will detail the results of our 2022 season, which is looking a lot like 2021.

One interesting drawback of high vacuum is the effect it has on the freezing point of water. Sap can be treated as water since it’s 98-99% water. We all know that water freezes at 32°F under normal conditions, but most people don’t know that under vacuum the freezing point can easily approach 35-40°F! In years past we noticed that even though the outside temperature would hover a few degrees above freezing, our releasers would fill with ice and sap would stop flowing. This is caused by the higher freezing point and amplified by leaks in the system. As air enters tubing through various leaks, it expands, releasing energy and dropping the localized temperature several degrees. These two effects work together, stopping sap flow prematurely.

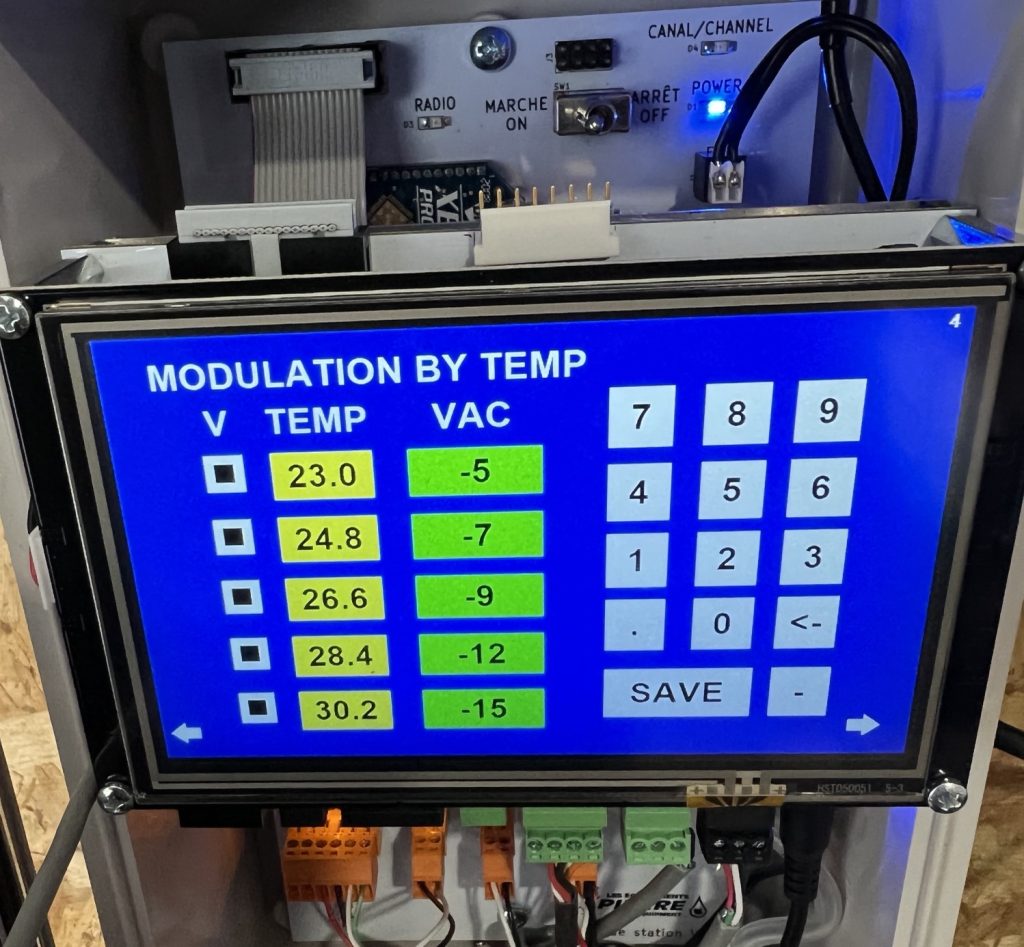

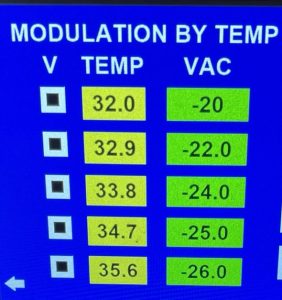

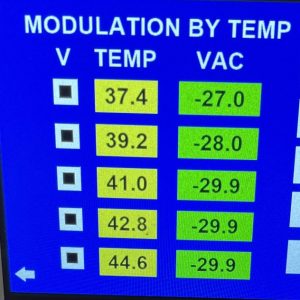

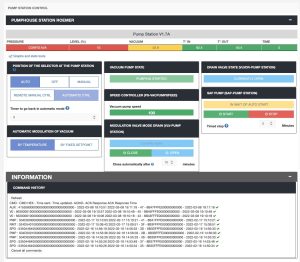

We always try to minimize leaks, but it is nearly impossible to find every micro leak over 110 miles of tubing. This year we’re fighting freeze ups another way, by adjusting our vacuum level based on the weather. As the air temperature approaches freezing, our pumps spin slower and our input line is chocked off by a modulating valve. We configure several temperature/vacuum set points to optimize sap flow but prevent freezing. Two additional benefits are that our pumps use less power when it’s below freezing, saving us hundreds of dollars in electricity each year, and that the modulating valve can be closed if the releaser floods, preventing our vacuum pump from sucking sap. We ran this system on three of our four properties this year and will be adding it to our fourth over the summer.